Our raison d’être has always been the protection of men and women at work. Due to the increasing demand for cut-resistant garments, we decided to extend our PPE know-how to include cut risks.

Our clients can have us design and manufacture cut-resistant garments and accessories to meet the needs of your profession, according to your constraints and the risks you encounter on a daily basis.

T-shirts, polo shirts, boleros, aprons, jackets, trousers or oversleeves: we can create 100% customisable garments:

For the manufacture of cut protection accessories (apron, neck warmer, arm warmers, etc.), we invite you to contact the EDC Protection team directly.

For the special manufacture of chainsaw clothing (T-shirts, polo shirts, jackets, pants, etc.), a special manufacturing study will be carried out through our parent company to confirm the feasibility of your project.

The fabric-selection stage is essential in the manufacture of reliable and effective cut-protection apparel;

indeed, each fabric we use has its own specific advantages in terms of the protection it delivers, and the end-choice will depend on your specific needs.

As a specialist, our role is to help you define your needs and choose the ideal fabric to design a personalised cut-resistant garment.

The new D1808 and D1809 fabrics provide unique levels of performance in terms of resistance against mechanical risks. These technical fabrics perfectly illustrate our constant desire to improve, in order to offer professionals the best possible performance in terms of protection.

Fabric composition: Crossed para-aramid

Weight: 240 gr/m²

Performance EN 388: 1340

Fine fabric providing a f irst level of protection against mechanical risks with level 3 cutting resistance.

Fabric composition: Para-aramid fabric with silicone coating

Weight: 600 gr/m²

Performance EN 388: 3532

Performance ISO 13997: 10.82N -> level C

Compliant with ISO 15025 & ISO 17493

Fabric offering level 4 resistance to cutting, and level 3 for abrasion and tearing. Its coated side is water and oil resistant. Can be used in high-temperature situations.

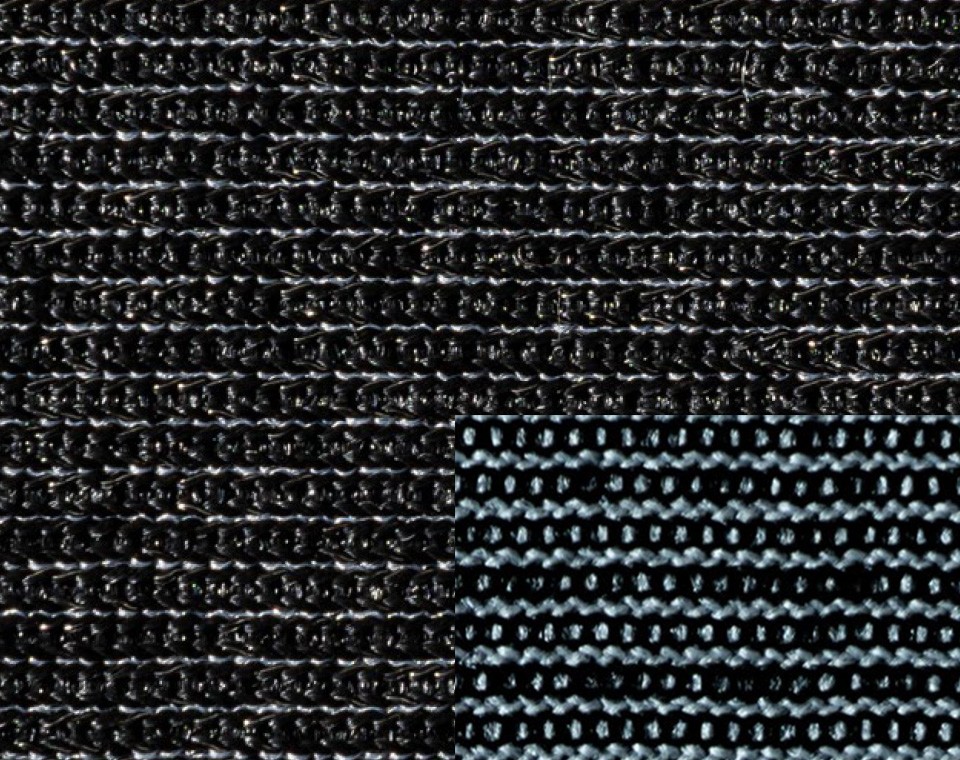

Fabric composition: Double-layer f lexible reinforcement Kozane® knit

Weight: 600 gr/m²

Performance EN 388: 4544

Performance ISO 13997: level E

Level 5 resistance to cutting and level 4 for puncture, tear and abrasion.

Available in fluorescent yellow version

Fabric composition: Double-layer f lexible reinforcement Kozane® knit

Weight: 600 gr/m²

Performance EN 388: 2544

Performance ISO 13997: level E

Available in black version

Fabric composition: High-performance polyethylene / ultra-fine steel wire / polyamide and polyester fibres

Weight: 389 gr/m²

Colour: white

Performance EN 388:

Abrasion resistance: level 3

Cut resistance: level X (test not adapted, see results of ISO 13997)

Tear resistance: level 4

Puncture resistance: level 3

Resistance to cutting by sharp objects ( ISO 13997): level E

ANSI ASTM F2992-15 performance: Cut-protection level A5 (score: 2.927 g)

The D1808 protective fabric is the lightest in its category. In terms of performance, it offers high levels of resistance to cuts, punctures, tears and abrasion. Developed for the manufacture of cut-resistant garments, this technical fabric is washable, breathable and soft to deliver comfort to the wearer.

Fabric composition: High-performance polyethylene / ultra-fine steel wire / polyamide and polyester fibres

Weight: 411 gr/m²

Colour: black

Performance EN 388:

Abrasion resistance: level 3

Cut resistance: level X (test not adapted, see results of ISO 13997)

Tear resistance: level 4

Puncture resistance: level 4

Resistance to cutting by sharp objects ( ISO 13997): level F

ANSI ASTM F2992-15 performance: A8 anti-cut protection (score: 5.215 g)

D1809 is the ideal compromise between comfort and efficiency in a single cut-resistant garment. It delivers exceptional levels of protection against mechanical risks by obtaining the best possible results in cut, tear and puncture tests. Designed for use in cut-protection garments, this technical fabric is washable, breathable and soft to deliver comfort to the wearer.