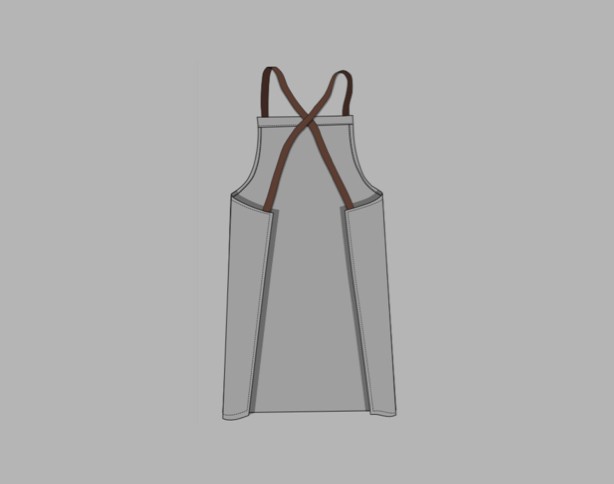

To meet the growing demand for cusrom PPE, we adapt our products to your constraints with a bespoke garment...

EDC Protection, a leader in the French personal protective equipment market, provides support and advice to all its customers on situations where there is a risk of death.

A true flag bearer for the Made In France movement, EDC Protection is proud to preserve its know-how at its historic Noviant-aux-Près site.

Each situation encountered is unique, and it is our duty to adapt our response to the end user’s environment.

The purpose of our made-to-measure service is to research and design solutions that offer optimum protection.

The list that we offer you is in no way exhaustive but represents the majority of the requirements that we encounter. We are at your service to look into any requirements for specific customisation.

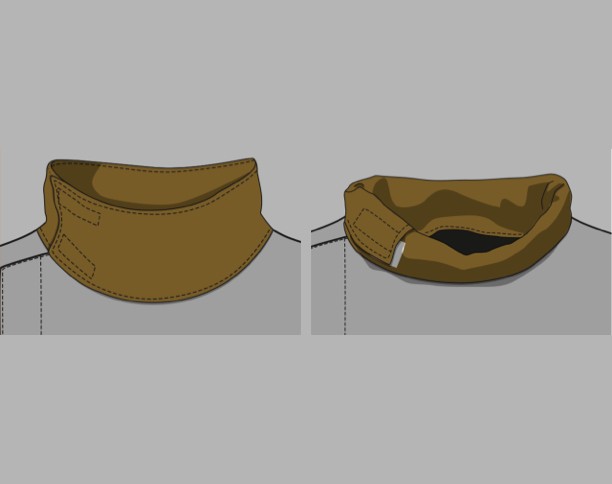

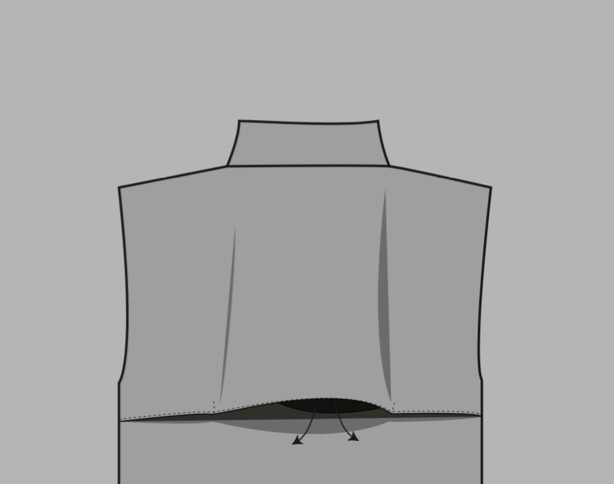

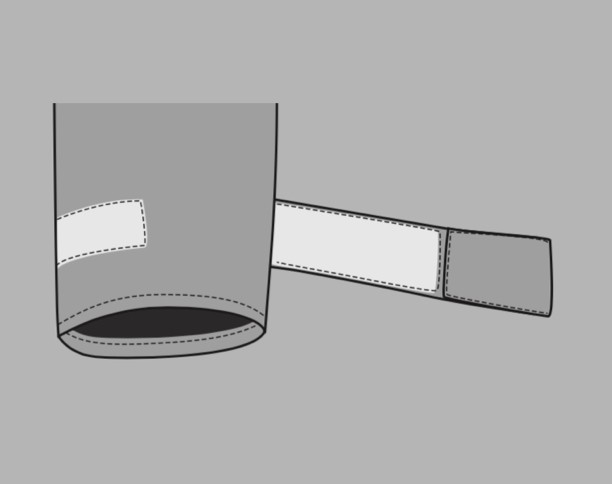

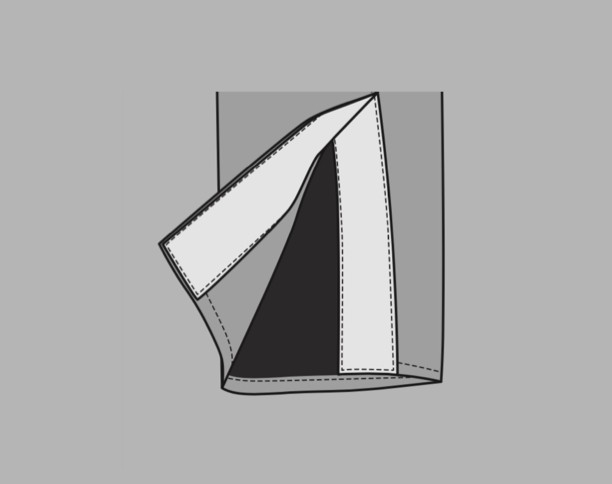

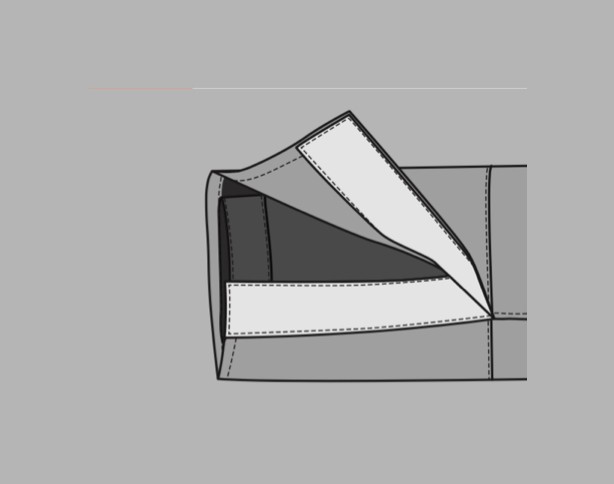

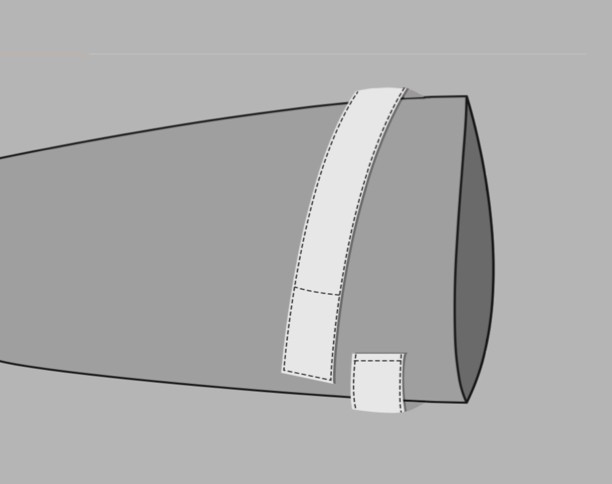

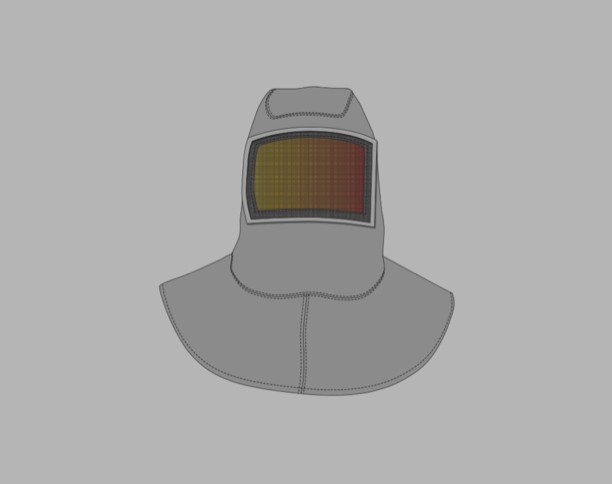

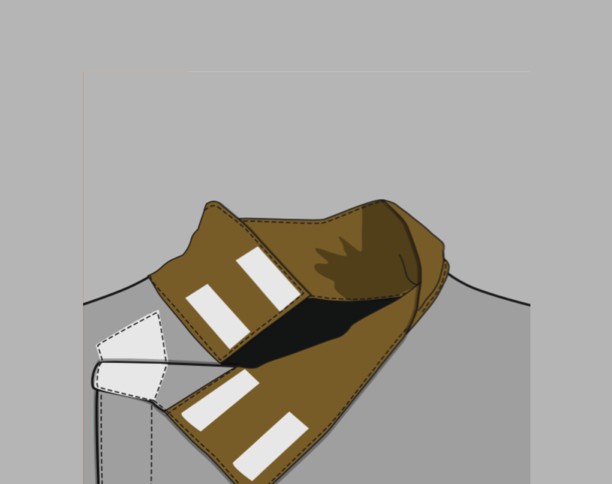

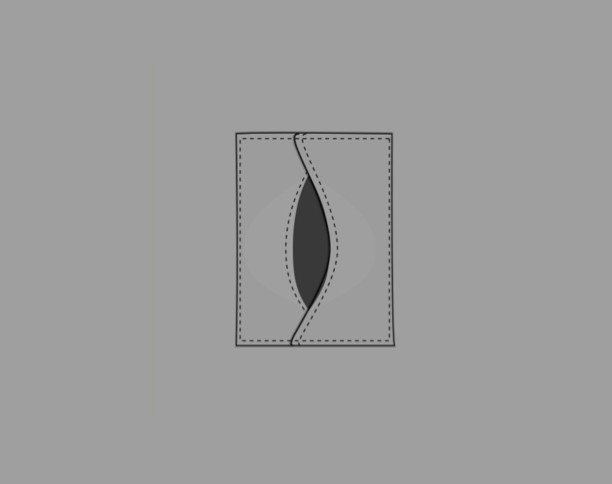

Possible variations:

Possible variations:

Possible variations:

Possible variations:

Possible variations:

Possible variations:

Possible variations:

Possible variations:

Possible variations:

Possible variations:

Possible variations:

Possible variations:

The risks for which our PPE is used are intense and extreme. EDC Protection is at your disposal to accompany you in your approach to PPE, to make recommendations, and to help you find the solutions that perfectly meet all your requirements.

Composition : Aluminised para-aramid

Aluminisation : Aluminised transfer foil

Weight : 500 gsm

ISO 11612 performance : A1 B1 C3 D3 E3

Standard fabric used in foundries, metal working, metal and steel working, etc. to cover risks that combine radiant heat and splashing. This fabric is our standard for protection from steel and cast iron.

Composition : Lightweight aluminised carbon/para-aramid (70/30)

Aluminisation : Aluminised PET foil

Weight : 340 gsm

ISO 11612 performance : A1 B1 C3 D3 E3

Very lightweight and f lexible fabric. The PET foil gives it a beautiful shine, making it ideal for jobs where there is less risk of splashing and/or comfort and light weight are important factors.

Composition : Aluminised carbon/para-aramid fabric (70/30)

Aluminisation : Aluminised PET foil

Weight : 520 gsm

ISO 11612 performance : A1 B1 C3 D3 E3

The PET foil gives it a beautiful shine and therefore great capability against radiant heat. Its medium weight means it deals with many of the issues of radiation and splashing. It is used in both the steel and aluminium businesses.

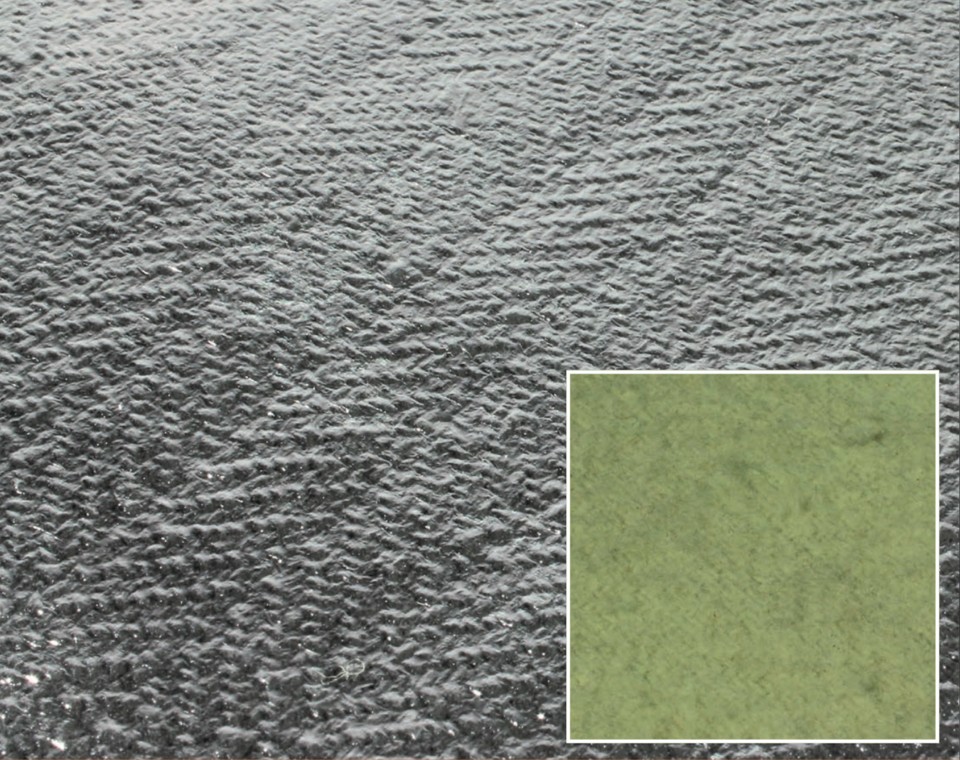

Composition : Aluminised carbon/para-aramid f leece (70/30)

Aluminisation : Aluminised PET foil

Weight : 430 gsm

ISO 11612 performance : A1 B1 C4 D3 E3 F1

The PET foil gives it a beautiful shine and therefore great capability against radiant heat. Its medium weight means it deals with many of the issues of radiation and splashing. It is used in both the steel and aluminium businesses.

Composition : Heavy aluminised carbon /para-aramid (70/30)

Aluminisation : Aluminised transfer foil

Weight : 680 gsm

ISO 11612 performance : A1 B1 C4 D3 E3 F1

Thick, resistant fabric that will cope with the biggest risks, exposure to radiation and in particular dangerous splashing.

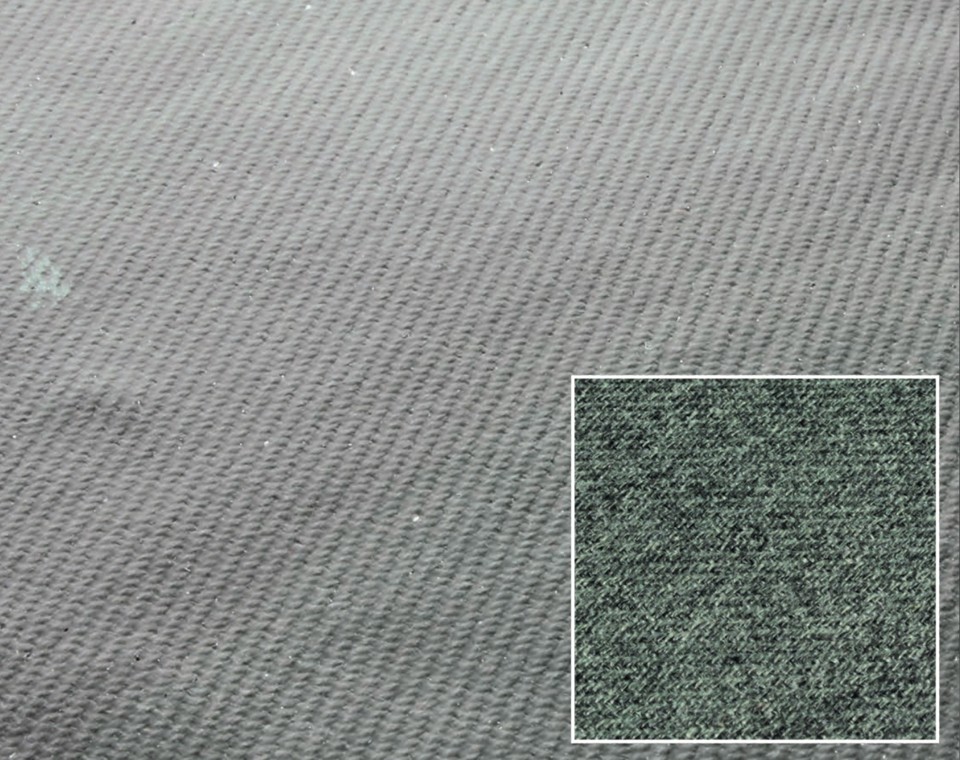

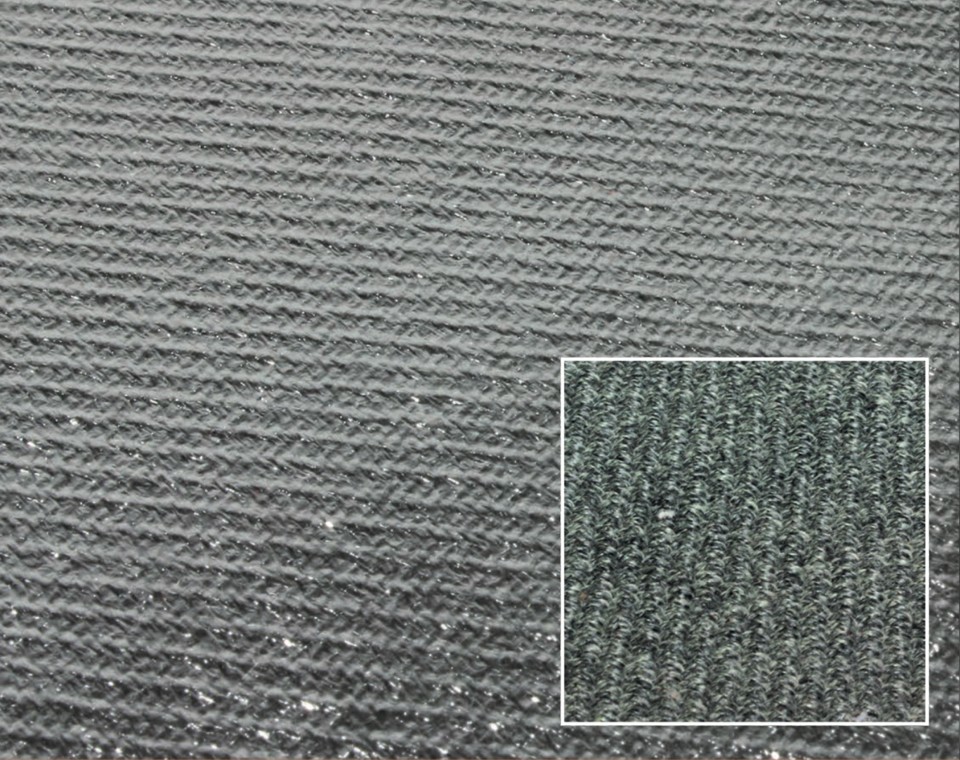

Composition : Crossed para-aramid

Weight : 240 gsm

EN 388 performance : 1340

Fine fabric providing a f irst level of protection against mechanical risks with level 3 cutting resistance.

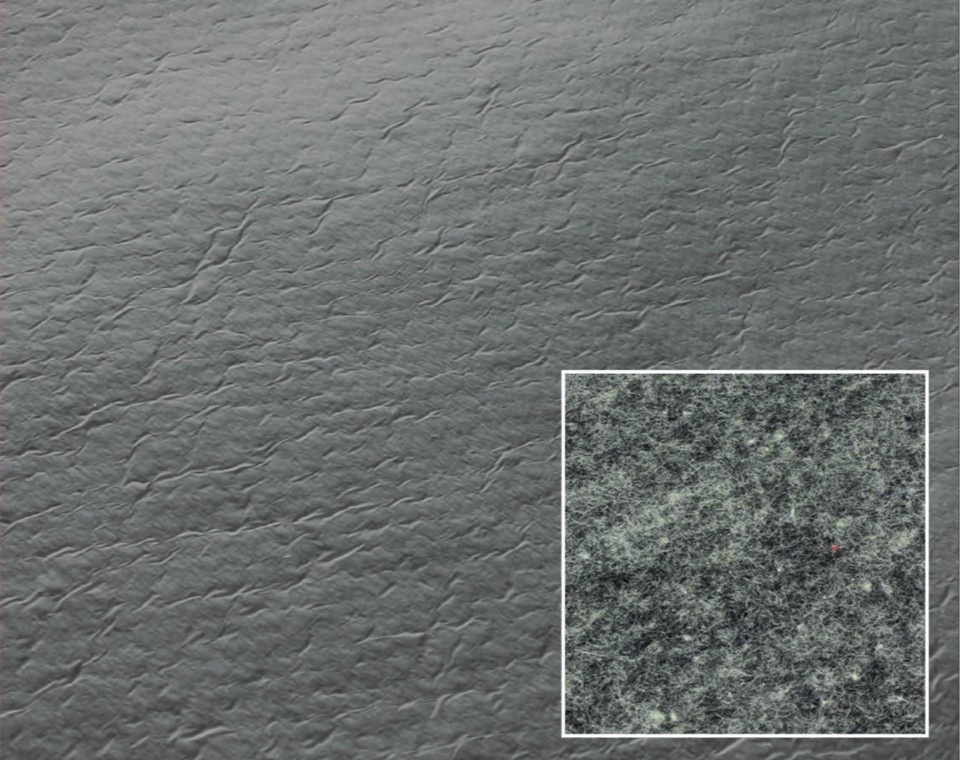

Composition : Para-aramid fabric with silicone coating

Weight : 600 gsm

EN 388 performance : 2532

ISO 13997 performance : 10.82N -> level C

Compliant with ISO 15025 & ISO 17493

Fabric offering level 4 resistance to cutting, and level 2 for abrasion and 3 for tearing. Its coated side is water and oil resistant. Can be used in high-temperature situations.

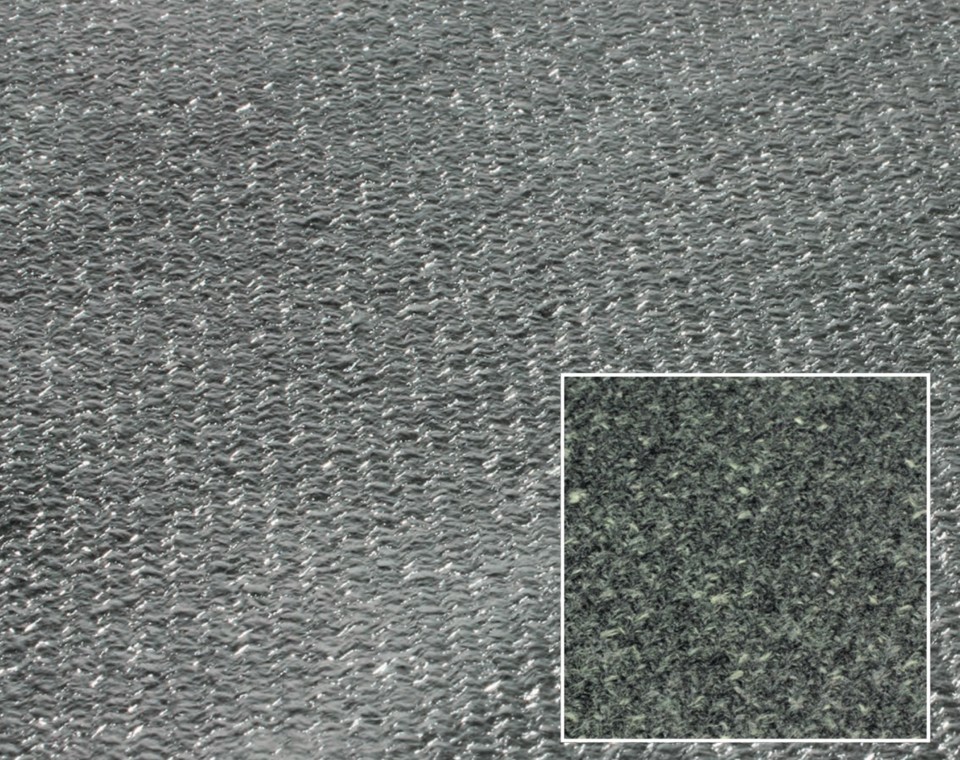

Composition : Double-layer f lexible reinforcement Kozane® knit

Weight : 600 gsm

EN 388 performance : 4544

ISO 13997 performance : level E

Level 5 resistance to cutting and level 4 for puncture, tear and abrasion.

Available in f luorescent yellow version.

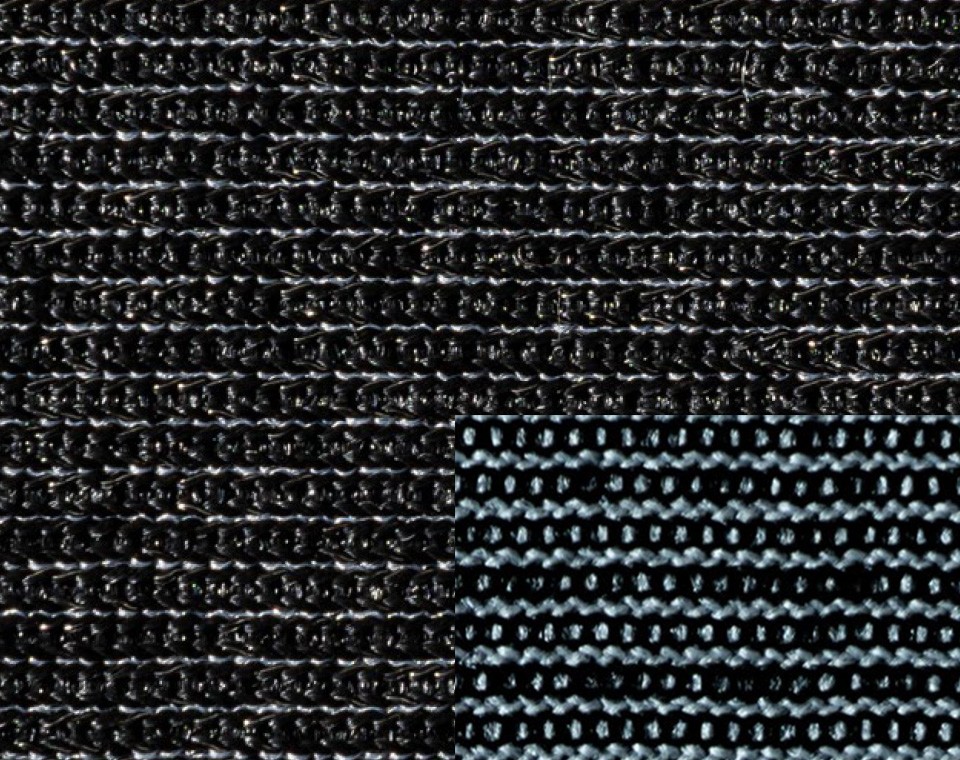

Fabric composition: Double-layer f lexible reinforcement Kozane® knit

Weight: 600 gr/m²

Performance EN 388: 2544

Performance ISO 13997: level E

Available in black version

Fabric composition: High-performance polyethylene / ultra-fine steel wire / polyamide and polyester fibres

Weight: 389 gr/m²

Colour: white

Performance EN 388:

Abrasion resistance: level 3

Cut resistance: level X (test not adapted, see results of ISO 13997)

Tear resistance: level 4

Puncture resistance: level 3

Resistance to cutting by sharp objects ( ISO 13997): level E

ANSI ASTM F2992-15 performance: Cut-protection level A5 (score: 2.927 g)

The D1808 protective fabric is the lightest in its category. In terms of performance, it offers high levels of resistance to cuts, punctures, tears and abrasion. Developed for the manufacture of cut-resistant garments, this technical fabric is washable, breathable and soft to deliver comfort to the wearer.

Fabric composition: High-performance polyethylene / ultra-fine steel wire / polyamide and polyester fibres

Weight: 411 gr/m²

Colour: black

Performance EN 388:

Abrasion resistance: level 3

Cut resistance: level X (test not adapted, see results of ISO 13997)

Tear resistance: level 4

Puncture resistance: level 4

Resistance to cutting by sharp objects ( ISO 13997): level F

ANSI ASTM F2992-15 performance: A8 anti-cut protection (score: 5.215 g)

D1809 is the ideal compromise between comfort and efficiency in a single cut-resistant garment. It delivers exceptional levels of protection against mechanical risks by obtaining the best possible results in cut, tear and puncture tests. Designed for use in cut-protection garments, this technical fabric is washable, breathable and soft to deliver comfort to the wearer.